- Combining world-class industrially proven technology with fermentation capacity, 21st.BIO helps customers get to scale faster, in a risk-mitigated and cost-effective way.

- Margrethe Vestager, Executive Vice President of the European Commission, was onsite to inaugurate the pilot facility, along a hundred other guests from the financial, political, and bio industrial sectors.

Copenhagen, Denmark, and Davis, California, 6 May 2024 – 21st.BIO unveiled a new pilot plant facility in its Danish headquarters, designed to support companies upscale their bioproduction.

21st.BIO provides services ranging from strain construction to industrial production upscaling to customers worldwide. Combining world-class industrially proven technology with fermentation capacity, the company will help customers get to scale faster, in a risk-mitigated and cost-effective way.

From left to right: Thomas Schmidt, co-founder and CEO at 21st.BIO, Margrethe Vestager, Executive Vice President of the European Commission, and Per Falholt, co-founder and CSO at 21st.BIO, unveiled 21st.BIO’s pilot plant facility

Why do we need pilot facilities? Upscaling mistakes cost a lot of money and time

“In this industry, upscaling mistakes cost a lot of money and time,” explains Thomas Schmidt, co-founder, and CEO at 21st.BIO. “For our customers, it’s all about getting the next step right. The ability to increase productivity when also moving up in scale is what distinguishes good from great.”

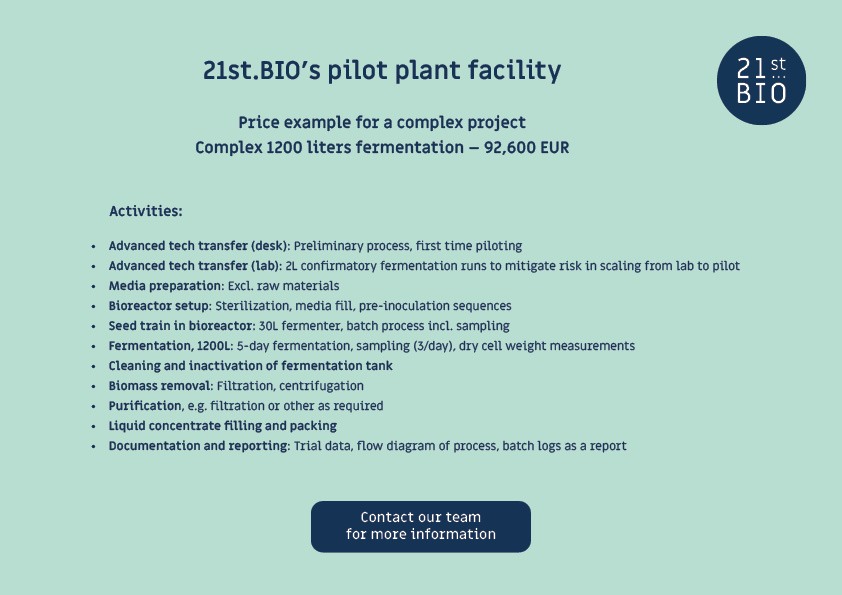

21st.BIO offers this pilot facility to the market to facilitate and accelerate the step between internal lab-scale fermentation and large-scale production. 21st.BIO’s pilot construction and deep experience are ideal to define the important parameters and equipment needed for optimal large-scale production of proteins via fermentation. This will, on top of the best fermentation protocols, for example also help customers select the best CMO for individual project needs and limit the risk of costly failures.

21st.BIO’s pilot facility is designed for industrial production upscaling

The facility and all processing equipment are state-of-the-art, with much equipment designed for 21st.BIO.

“Our goal with this pilot was to build a mini factory, to best prepare customers for large scale industrial production. We therefore wanted the process equipment to mimic what customers will find in their next step with large-scale biomanufacturing – only downsized to a pilot scale,” explains Thorvald Ullum, Chief Technology Officer at 21st.BIO. He adds “our customers work alongside our experts in the pilot plant to test various process aspects as well as build skills and confidence for their own large-scale production.”

With over 3000 liters of fermentation capacity, the facility offers a full range of capabilities, equipment, and competences to help customers optimize their own specific processes. The pilot plant is focused on scaling up the production of recombinant proteins and peptides with applications in nutrition, food and beverages, agriculture, biomaterials, and biopharma.

The pilot plant is designed to enable strong collaboration between 21st.BIO and customer teams during scaling. The facility is strategically located in the same building as the company’s strain development laboratories, allowing for joint work on further improving the customers’ production strains and fermentation processes.

21st.BIO’s pilot welcomes established industry leaders in ingredient manufacturing as well as early-stage startups.

The global race for biosolutions is on

Home to precision fermentation pioneers such as Novo Nordisk and Novonesis, Denmark is a natural leader in bioproduction. According to a McKinsey report, it is estimated that about 60% of the input to the global economy could over time be produced using biology. Because of this potential, many countries are investing massively in biomanufacturing technology to produce high quality nutrition and biomaterials locally in a time of climate and geo-political uncertainties.

Europe has an opportunity to bring this leading technology and know-how to benefit the world. Therefore, 21st.BIO’s grand opening began with an exclusive roundtable, where twenty C-level participants from the political, financial, and industrial horizons had a lunch conversation over EU countries’ leadership in the industrial scaling of biomanufacturing.

Margrethe Vestager, Executive Vice President of the European Commission, attended the event and underlined the high potential of the biotech sector to address key challenges ranging from ensuring sustainability to stabilising global food chains. She emphasised Europe’s leadership in science, while acknowledging that taking science to markets is often hindered by lack of sufficient funding, long regulatory procedures, and a reduced talent pool. She also called for cooperation between policy makers and industry players to ensure that policies are designed while taking into account the industry’s lessons learnt.

Earlier in March, the European Commission presented its “Communication on Biotech and Biomanufacturing” and with that a series of actions to boost the sector in the EU. This includes working towards simplified regulatory framework and faster access to market, better support for scale-up, a fairer comparison with fossil-based products, and the encouragement for more investments to go into biotechnologies and biomanufacturing in the coming years.

As Margrethe Vestager said during the press conference, “Europe cannot just be the cradle for new solutions, what is born here should also grow up and stay here.”

Ambitions for enabling the building of large-scale protein facilities across the world

21st.BIO founders saw that too often; great bio innovations and molecules fail to translate into commercial success. The molecule innovation is ready and exciting, the market is there, but production costs most often have remained too high for the products to go mainstream and hence have real relevance for the world.

A recent report by Boston Consulting Group highlighted that three parameters were key to get down the cost of bioproducts: Production strains designed for scale, mega scale factories of over two million liters capacity, and mass market demand. This is what 21st.BIO is all about.

21st.BIO is now making the most advanced and most productive production technology and know-how available to innovators in industrial biotech as well as global food majors for bulk products to be produced via fermentation. The pilot facility will support customers’ journey from the lab to large scale manufacturing, but the journey towards industrial biomanufacturing does not stop there. During the inauguration, senior leaders from key players of the financial, political, and industrial sectors participated in a roundtable discussion on what it will take to start building the first large-scale protein factories with all the benefits of industrial manufacturing to cost and efficiency.

About 21st.BIO

Founded in 2020, 21st.BIO is headquartered in Copenhagen, Denmark, and has a world-class R&D team as well as laboratories in both Copenhagen, Denmark and Davis, California. On a mission to support bio industrial companies globally in upscaling from molecule innovation to large-scale production, 21st.BIO enables its customers to meet market demands, and thereby advance the green transition globally. 21st.BIO focuses on developing industrial production technology for proteins and other molecules of interest for food, materials, and agricultural industries. Established as a fully integrated end-to-end partner, 21st.BIO supports its customers from technical assessment, strain development and optimization, production processes and upscaling, tech transfer to large scale manufacturing and regulatory services.

21st.BIO was founded with one simple mission: to make industrial scale precision fermentation technology accessible to as many as possible, so companies can successfully take their biotech innovations to market at a competitive price.

21st.BIO’s fermentation technology is in part licensed from Novonesis, who has developed their platform over several decades. Novonesis is a global leader in enzymes and proteins for high value products in food, household care, and agriculture, with a market value of approximately 6 billion USD.

For more information and pictures of the day, please contact:

Mathilde Pinon

Marketing & Business Development Manager

+4531543184

m.pinon@21st.bio