We are thrilled to announce the publication of our latest scientific paper, “The Next Food Revolution Is Here: Recombinant Microbial Production of Milk and Egg Proteins by Precision Fermentation” in Annual Reviews of Food Science and Technology.

This work is authored by our brilliant colleagues José Arnau, R&D Director, and Morten Bjørn Nielsen, Industrial PhD student.

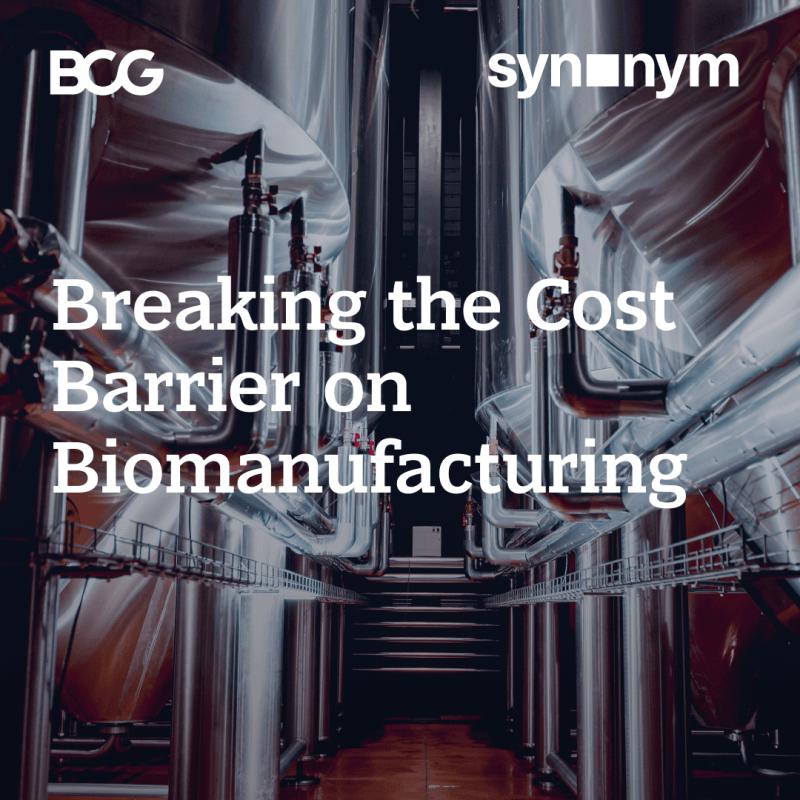

In a world where food production must be drastically increased to meet the demands of a growing population and simultaneously made sustainable to respect and preserve our planet, precision fermentation offers a revolutionary solution.

Using microbes to produce animal-identical proteins, precision fermentation is set to transform our food systems. This technology is incredibly efficient regarding land, water, and feedstock use, and is expected to make food production sustainable and to result in more local production of designed food products, such as dairy or egg proteins.

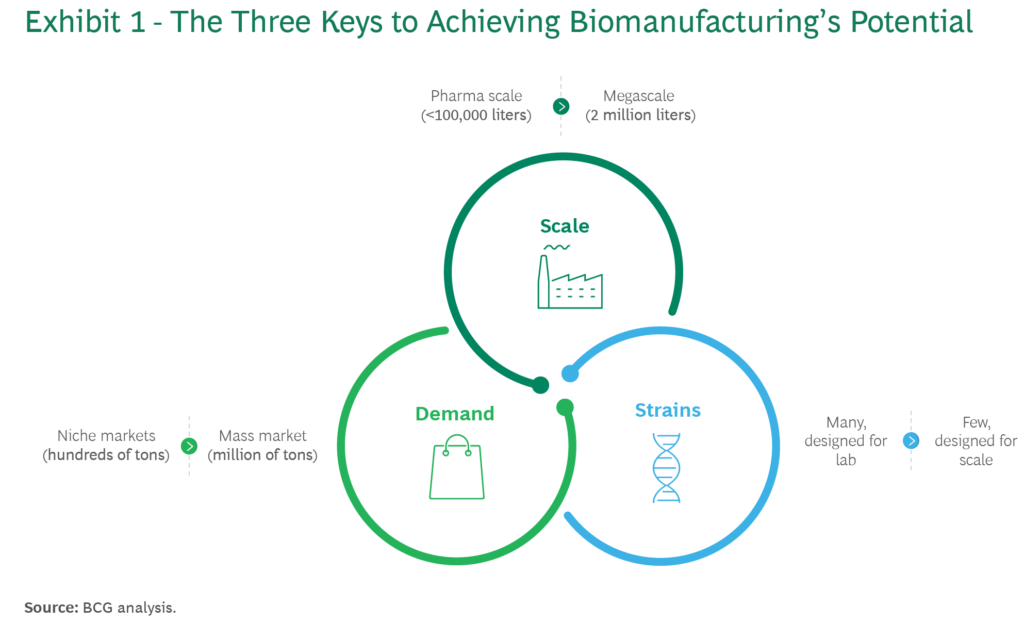

But for this food revolution to happen, the technology needs to scale, with production titers reaching 50 g/L and above. This requirement makes strain engineering, process optimization and scale-up critical success factors. And that’s why we at 21st.BIO make it our mission to develop the best production strains and fermentation processes, continuously optimizing every single step, and supporting our customers to upscale towards industrial production. We do it so you don’t have to.

Our top-performing strains are already working with dairy and egg proteins. Explore our development programs, and contact us for more information.

We strongly recommend this read to better understand precision fermentation and its potential. Whether you’re a seasoned expert or just curious, this paper has valuable insights for everyone.