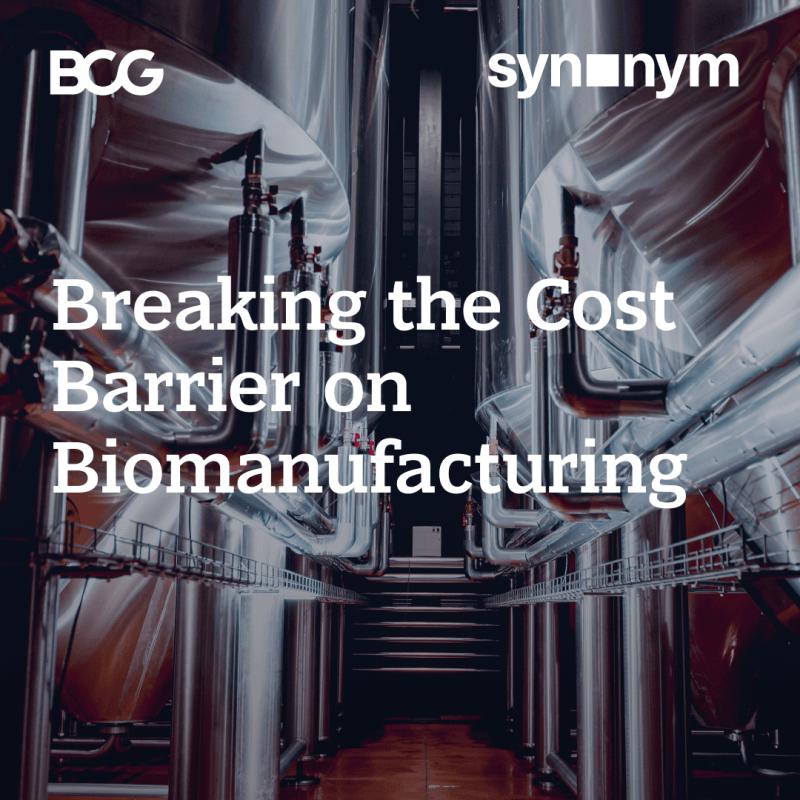

“How to get precision fermentation biomanufacturing to cost-efficiency?”

That’s precisely the question Boston Consulting Group‘s latest report, ‘Breaking the cost barrier in Biomanufacturing’, intends to answer. The report was written in collaboration with Synonym, with contributions from our co-founder and CSO, Per Falholt.

Biosolutions hold immense promise to revolutionize the food, specialty chemicals, and biomaterials industries. With increasing global demand for sustainability and emissions reduction, there is a pressing need for economically viable biomanufacturing at scale.

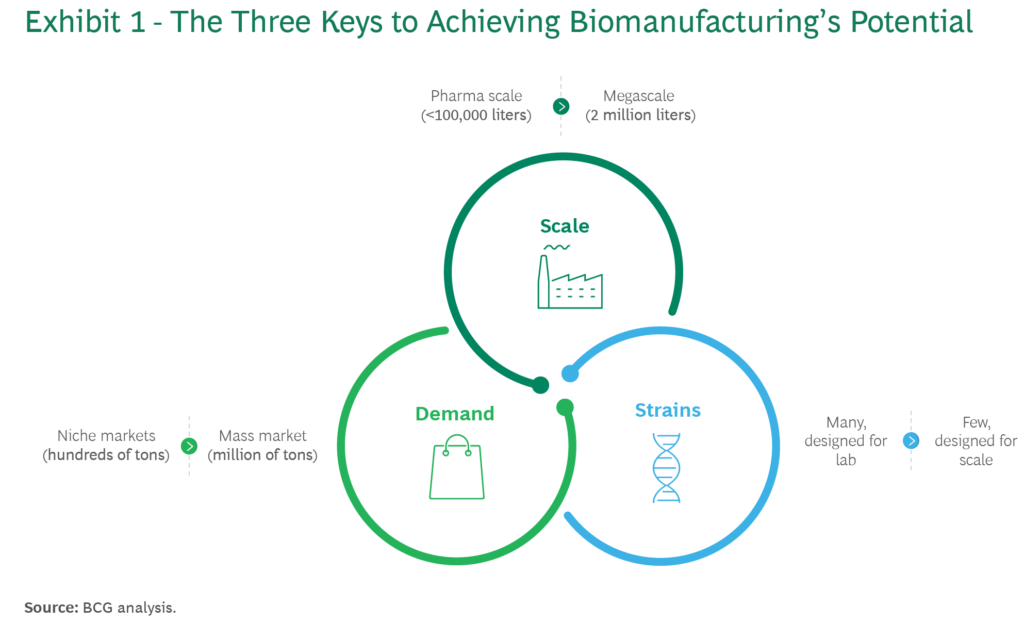

But how do we get there? The solutions are trifold:

▶ optimization of large-scale facilities,

▶ production technology (strains and processes) designed for industrial scale,

▶ collaborative efforts among stakeholders — from corporate customers to policymakers — to drive investment and infrastructure development.

According to the report, all these efforts would pave the way for a $200 billion market by 2040.

The report also insists on the importance of developing production strains designed for large scale.

At 21st.BIO, we are proud to say that our strains are designed for industrial scale. With our technology platform, the industry can move forward to the next stage.

Developing microbial strains designed for scale is a tremendous challenge. While many strains might do very well in lab conditions, upscaling production to industrial scale remains an obstacle for most companies.

In the report, BCG estimates that producing strains optimized for large-scale manufacturing in optimized large-scale biofoundries could bring costs down by 90%.

Our company was founded with one simple mission: to make precision fermentation technology accessible to as many companies as possible, so they can successfully take their product to market at a competitive price.