Beta-lactoglobulin (BLG) presents outstanding nutritional values, as well as foaming, emulsifying, and gelling properties. This key dairy protein can enhance the nutrition, texture, and stability of plant-based or hybrid products, as well as dairy alternatives.

PRECISION FERMENTED

DAIRY PROTEINS

As global demand for dairy proteins soars and traditional production struggles to keep up, precision fermentation emerges as a revolutionary solution, ready to secure the future of our food supply with game-changing innovation.

AN ALTERNATIVE IN HIGH DEMAND

The United Nations expect the global demand for protein to double by 2050. But not all proteins are born equal: dairy proteins offer the best nutrition, digestibility, and functionality. Demand for dairy proteins is expected to increase globally, while production could stagnate, if not decrease, in most regions. Dairy market reports highlight production gaps of 20 to 30 million tons of milk equivalents already by 2030.

Developing alternative methods, such as precision fermentation, is crucial to securing global food supply chains. Luckily, it’s not such a distant future.

With 21st.BIO, precision fermented dairy proteins are already a reality.

INGREDIENTS OF INTEREST

BETA-LACTOGLOBULIN

Our BLG-Essential+™ is a highly nutritious recombinant beta-lactoglobulin with self-affirmed GRAS status. Join our development program and enter the US market immediately.

Beta-lactoglobulin contains 45% more leucine than commercially available whey protein isolates, which is particularly important for muscle synthesis. It is tasteless, stable across a wide pH range and can tolerate heat, making it the ideal ingredient for versatile product formulations, from clear protein drinks to alternative dairy or bakery products.

CASEINS

Caseins are a group of milk proteins making up about 80% of the protein content in cow’s milk. They are particularly researched for their role in forming curds during cheese production. Caseins are rich in essential amino acids and contribute to various functional properties in food, such as improving texture and stability.

We are working on most casein recombinants. Set up a meeting with our team for more details.

WELCOME TO THE FOREFRONT OF PRECISION FERMENTATION

The world needs new solutions to tackle the mounting sustainability challenges. Precision fermentation offers new ways to produce the food, materials, and chemicals we need, sustainably.

Joining a 21st.BIO development program grants you access to world’s most advanced precision fermentation technology platforms.

Far too often, promising molecular innovations failed to make a real impact – or even be commercialized – due to difficulties in achieving cost-effective large-scale production.

Enters 21st.BIO – the precision fermentation launchpad. Our industrially proven technology platform leverages the most experienced production strains available. We accelerate the world’s quest for biosolutions – and make your innovations truly relevant.

OUR PROMISE: INDUSTRIALLY PROVEN PRODUCTION TECHNOLOGY

Working with 21st.BIO means accessing the world’s most advanced precision fermentation technology platform. Perfected over 40 years, our strains are used to produce dozens of food-grade products on the market today.

We are committed to offering a limited number of manufacturers access to our cutting-edge production technology. Working on beta-lactoglobulin for the past years, our strains have already reached unmatched productivity, and product quality. Our customers are already scaling, and we are now ready to onboard more pioneers and move the industry forward.

HOW DOES IT WORK?

YOU ARE:

- A visionary start-up exploring the development and production of one or several dairy proteins.

- An established food manufacturer expanding its portfolio with sustainable ingredients.

- A leading dairy company dedicated to lowering its environmental impact while meeting market demand for high quality nutrition.

YOU GET:

- Access to our leading production technology, enabling unmatched productivity, and used in several food applications already,

- Custom support in scaling the production from a world class expert team, in a transparent collaborative setting,

- Transfer of our production technology in your own labs and production facilities, or to a contract manufacturer,

- Time to focus on developing your own purification processes, optimized for the desired functionalities applications,

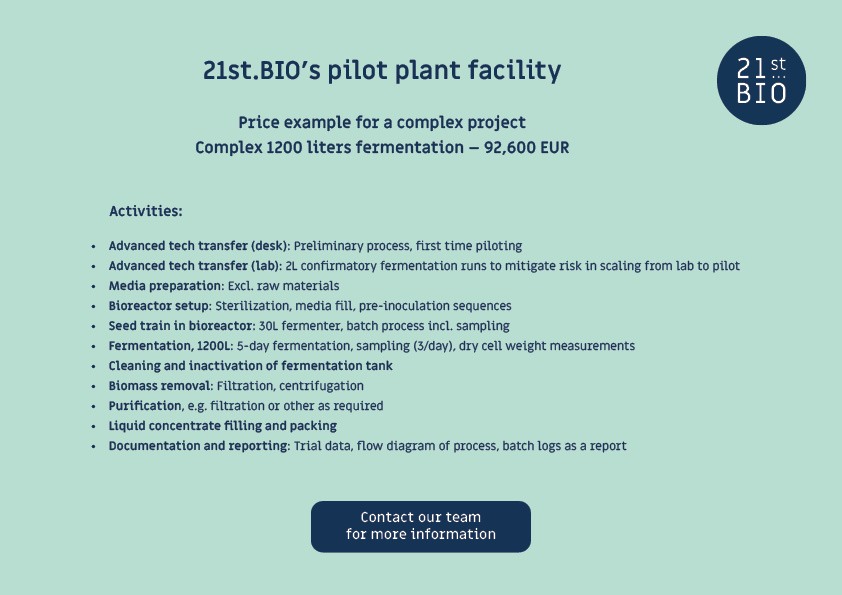

- Access to our in-house pilot facility, for runs up to 1200 liters,

- Consulting services for strain engineering, fermentation & DSP, pilot production, regulatory approvals, scale up and tech transfer,

- Continuous optimization of strains and processes, to stay ahead of the game long after market launch.

JOIN OUR DEVELOPMENT PROGRAMS

Our development programs enable the fast and cost-efficient industrial production of beta-lactoglobulin and caseins.

Capitalizing on our mature fungal production strain, these programs are offered to a limited number of companies who share the development costs. Participants are given a license to use our strain and processes.

Over time, 21st.BIO will continue to optimize the strain and processes, continuously keeping you ahead of the market.