Precision fermentation offers a genuine solution by using microbes to produce truly vegan collagen, delivering the same benefits as traditional collagen but without animal involvement. Precision fermentation also opens new doors for recombinant collagens, designed and modified to meet performance criteria for new applications. This is the future of collagen, reshaping the industry with sustainability and innovation at its core. Bioproduction of collagen ensures both authenticity and alignment with ethical consumer values.

PRECISION FERMENTED

COLLAGEN

THE ONLY ANIMAL-FREE COLLAGEN

Collagen has become a cornerstone of beauty, wellness, and nutrition, celebrated for its role in everything from youthful skin to joint health. But traditional collagen sourcing isn’t without its drawbacks, from animal welfare concerns to environmental impact. As consumer awareness grows, there's increasing demand for vegan alternatives. While many products labeled as “vegan collagen” rely on plant-based peptides that support the body’s own collagen production, they don't actually contain collagen.

WELCOME TO THE FOREFRONT OF PRECISION FERMENTATION

OUR PROMISE: INDUSTRIALLY PROVEN PRODUCTION TECHNOLOGY

Working with 21st.BIO means accessing the world’s most advanced precision fermentation technology platform. Perfected over 40 years, our strains are used to produce dozens of food-grade products on the market today.

We are committed to offering a limited number of manufacturers access to our cutting-edge production technology. We have real experience with what it takes to bring these protein sweeteners to relevant price-points for mass-market consumer relevance. We can help you too.

HOW DOES IT WORK?

YOU ARE:

- A visionary start-up exploring the development and production of one or several types of collagens (I, II, III, V, X…).

- An established supplier expanding its portfolio with sustainable, animal-free ingredients.

YOU GET:

- Access to our leading production technology, enabling unmatched productivity, and used in several food applications already,

- Custom support in scaling the production from a world class expert team, in a transparent collaborative setting,

- Transfer of our production technology in your own labs and production facilities, or to a contract manufacturer,

- Time to focus on developing your own purification processes, optimized for the desired functionalities applications,

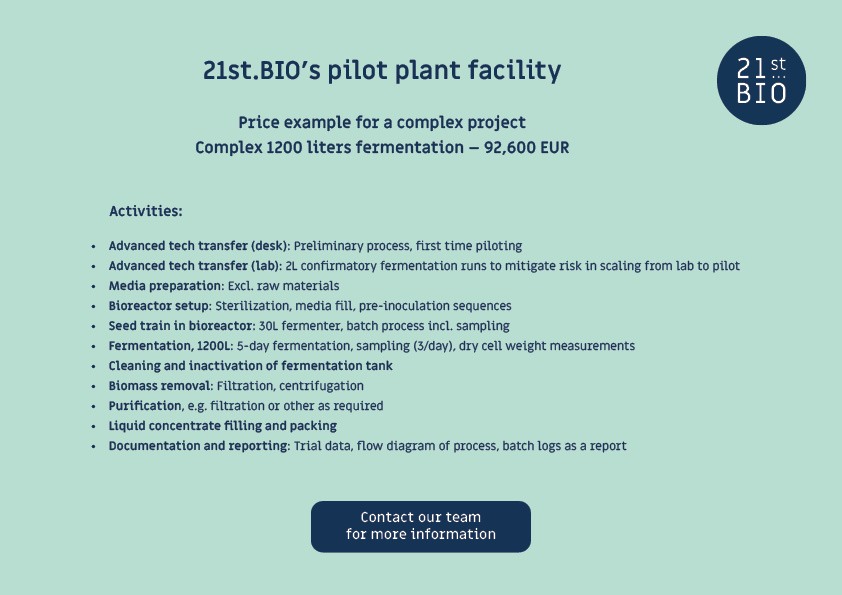

- Access to our in-house pilot facility, for runs up to 1200 liters,

- Consulting services for strain engineering, fermentation & DSP, pilot production, regulatory approvals, scale up and tech transfer,

- Continuous optimization of strains and processes, to stay ahead of the game long after market launch.

OPEN A DEVELOPMENT PROJECT

Our precision fermentation technology can enable a fast and cost-efficient industrial production of the different types of collagen.

We offer custom development projects tailored to meet your specific needs, focusing on optimizing your proprietary recombinant protein. Capitalizing on our mature fungal production strain, these projects can include strain optimization, production process design, and technology upscaling.

Over time, 21st.BIO will continue to optimize the strain and processes, continuously keeping you ahead of the market.