Our collaboration with German biotech AMSilk, covered in Nature Biotechnology, is enabling the large-scale production of various spider silk proteins used in biomedical, cosmetics, and textile industries.

PRECISION FERMENTED

BIOMATERIALS

Precision fermentation holds the potential to revolutionize biomaterial production by enabling the creation of sustainable, high-performance materials with tailored properties for diverse industries.

THE FUTURE IS BIOMADE

Materials are the fabric of our technological progress, and the need for sustainable alternatives has never been more critical. Renewable and biodegradable, biomaterials emerge as an option.

From biopolymers and specialty chemicals to synthetic proteins, precision fermentation stands out as the most efficient solution to produce sustainably, and ensure a resilient supply chain with limited impact on the environment.

A SILK-STRONG PARTNERSHIP

AMSilk x 21st.BIO: taking spider silk to the next level

Our technology and expertise led to industry milestones:

- World’s first extracellular expression of spider silk proteins, enabling scalable production.

- Production upscaling to unprecedented levels, opening a middle-value market to expand accessibility.

For its unparalleled combination of strength and flexibility, spider silk is the gold standard of bioindustrial materials. Not only is biosilk produced via precision fermentation mechanically superior, it is also fully biocompatible. It has unlimited applications ranging from biofilms, home textiles, footwear, bags, and even composites for automobile.

We are very proud to continue supporting AMSilk in leading the field with industrial scale supplies of high-performance materials.

”By partnering with 21st.BIO, we are succeeding where so many have struggled, delivering high performance precision fermentation at the right quality and cost parameters, and at a true industrial scale.

Ulrich Scherbel, CEO, AMSilk

WELCOME TO THE FOREFRONT OF PRECISION FERMENTATION

Working with 21st.BIO means accessing the world’s most advanced precision fermentation technology platform. Perfected over 40 years, our strains are used to produce dozens of food-grade products on the market today.

Far too often, promising molecular innovations failed to make a real impact – or even be commercialized – due to difficulties in achieving cost-effective large-scale production.

Enters 21st.BIO – the precision fermentation launchpad. Our industrially proven technology platform leverages the most experienced production strains available. We accelerate the world’s quest for biosolutions – and make your innovations truly relevant.

OUR PROMISE: INDUSTRIALLY PROVEN PRODUCTION TECHNOLOGY

We are committed to offering a limited number of manufacturers access to our cutting-edge production technology. We have real experience with what it takes to bring these protein sweeteners to relevant price-points for mass-market consumer relevance. We can help you too.

HOW DOES IT WORK?

YOU ARE:

- A visionary start-up exploring one or several promising compounds.

- An established supplier expanding its portfolio in sustainable alternatives.

YOU GET:

- Access to our leading production technology, enabling unmatched productivity, and used in several food applications already,

- Custom support in scaling the production from a world class expert team, in a transparent collaborative setting,

- Transfer of our production technology in your own labs and production facilities, or to a contract manufacturer,

- Time to focus on developing your own purification processes, optimized for the desired functionalities applications,

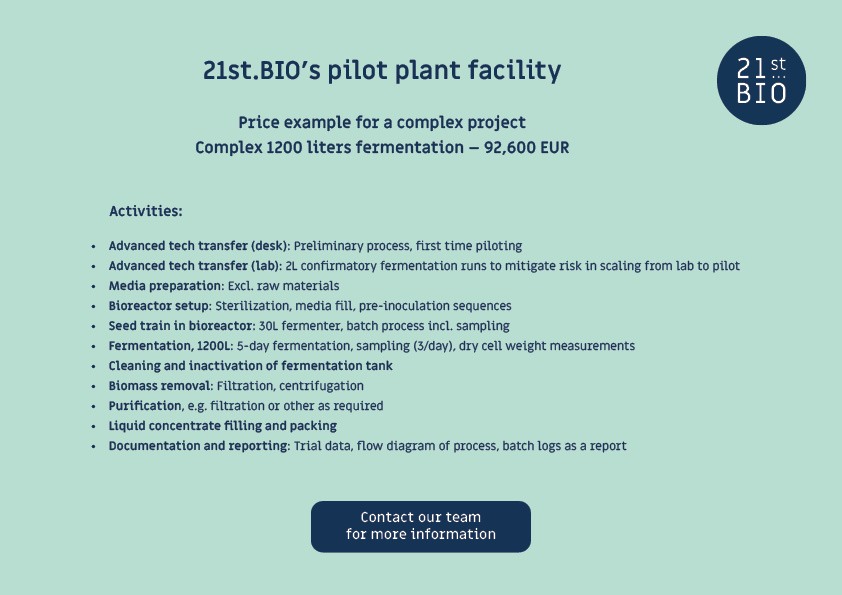

- Access to our in-house pilot facility, for runs up to 1200 liters,

- Consulting services for strain engineering, fermentation & DSP, pilot production, regulatory approvals, scale up and tech transfer,

- Continuous optimization of strains and processes, to stay ahead of the game long after market launch.

OPEN A DEVELOPMENT PROJECT

Our precision fermentation technology can enable a fast and cost-efficient industrial production of various biomaterials.

We offer custom development projects tailored to meet your specific needs, focusing on optimizing your proprietary recombinant protein. Capitalizing on our mature fungal production strain, these projects can include strain optimization, production process design, and technology upscaling.

Over time, 21st.BIO will continue to optimize the strain and processes, continuously keeping you ahead of the market.